About gravionExcellence in Embossing

gravion combines precision, innovation, and expertise to deliver high-quality embossing solutions for industries worldwide. With a focus on tailored rollers, coatings, and full-service systems, we transform ideas into reliable, performance-driven products. Our commitment to sustainability, consistency, and customer partnership ensures every solution meets the highest standards of quality and efficiency.

Our ExpertiseTurning Ideas into Reality

From concept to finished embossing solution, we craft every detail with precision and care.

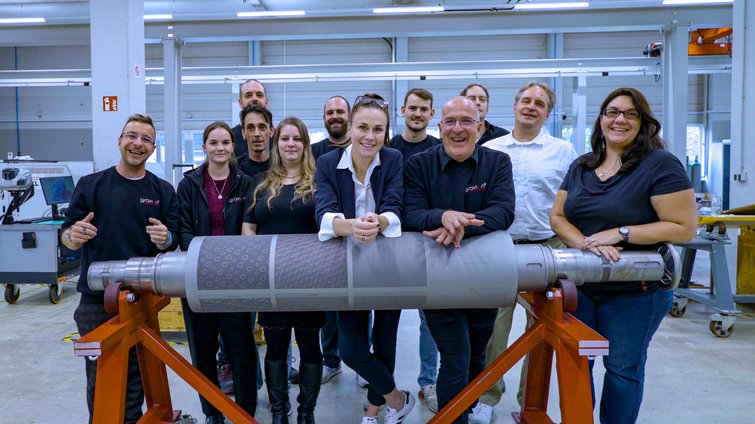

ProductionGlobal Leaders in Laser Technology

With strategically located production sites across Europe and the USA, gravion ensures fast delivery, local support, and seamless service worldwide. Each facility combines precision technology with expert craftsmanship to deliver consistent quality. Our global presence allows us to respond quickly to customer needs while maintaining the highest standards of performance and reliability.

Rheinfelden, Germany

Our 2,000 m² Competence Center is where precision meets innovation. Steel, copper, HSS — any material, directly laser-engraved. Rollers up to 4.25 m long, 3.6 m embossing width, 510 mm diameter, depths up to 6 mm.

Key Facts:

- Rapid project execution

- Superior precision over outdated methods

- Eco-friendly, acid-free production

- Energy-efficient processes

- Fully open for custom designs

- Process-integrated 3D measurement ensures process-safe, consistent quality

gravion GmbH

79618 Rheinfelden, Germany

Ball Ground, Georgia, USA

Our 1,500 m² US site mirrors Germany: same machines, 3D measurement tools, and digital workflows — delivering consistent global standards.

Key Facts:

- Same precision and eco-conscious processes as Rheinfelden

- Full compatibility with German facility for seamless production

- Process-integrated 3D measurement for inline quality control

gravion USA Inc.

30107 Georgia, North America

CommunicationYour contact partners

Are you buzzing with ideas about roller technology? Become part of the gravion team.

SustainabilityImproving Efficiency

One thing is crystal clear to the company's founder: "Our resources are finite and will not become cheaper in the long term.

As a result, at gravion we scrutinize existing technology and spend every day developing more efficient solutions."

For instance, the gravion team has reduced the amount of waste produced by the manufacturing process by such an extent that a regular trash will hold it all. The power that gravion uses comes from renewable sources of energy. The roof of the company's premises is used to generate power and even rainwater is collected, treated and re-used.

Dietmar Buchholz and his team put everything they've got into acting in line with the company's motto: Be different – be innovative!